-

Products

-

IndustriesThe products are widely used in many industries, indluding shipbuilding, offshore engineering, petrochemical engineering, electric power, vehicle industry.

-

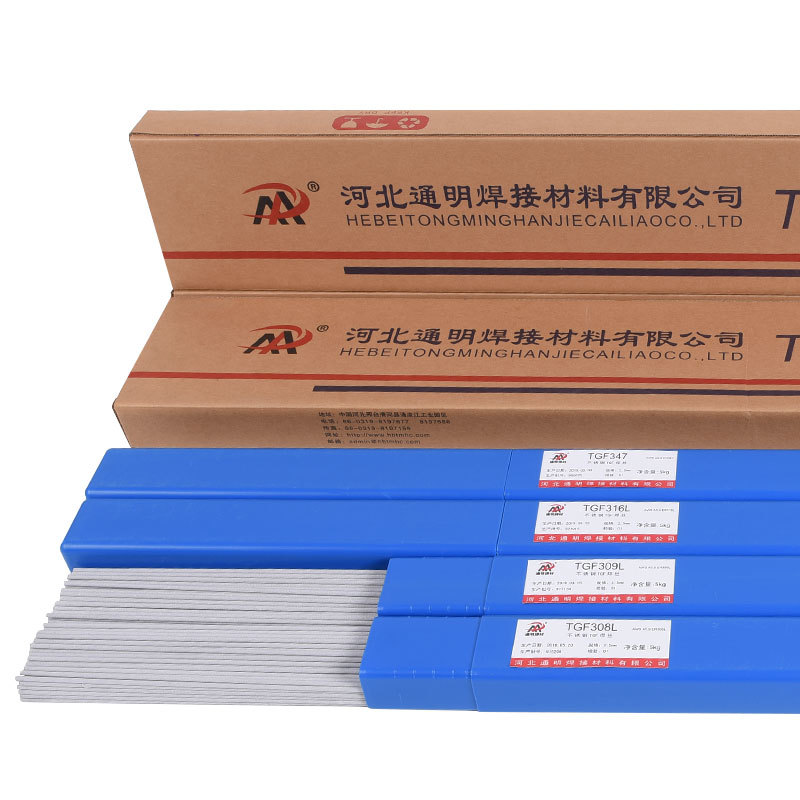

About UsTONGMING is one of the leading welding materials manufacturers in China. Since the inception of our operations in 2002, we have adhered to the highest standards of quality, research and innovation, and customer service.

-

NewsOur products have passed ISO9001 quality system certification, and have certified as high quality products by third parties from industries, such as nuclear power boiler and shipbuilding.

Since 2002, Tongming welding materials has been supplying the highest quality alloy welding consumables products.

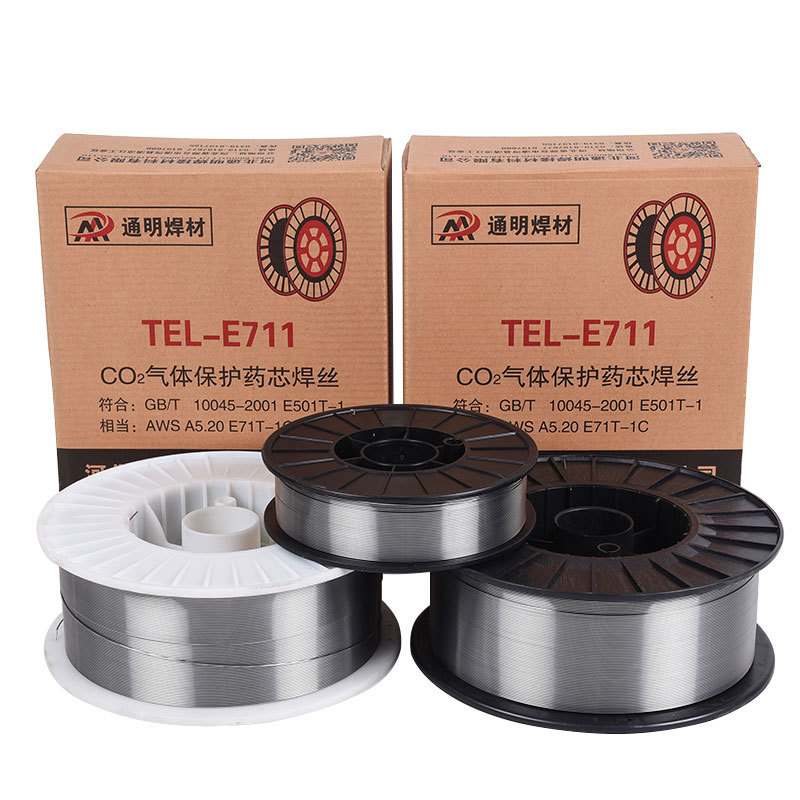

Learn More →Our Products

We knows that consistent, high-quality welds are the key to your success. Whether for industrial manufacturing or heavy fabrication, find all of your welding consumables solutions here.

Choose Products

Choose Products

Welding repair of cast iron nickel-based welding materials

Choose Products

Choose Products

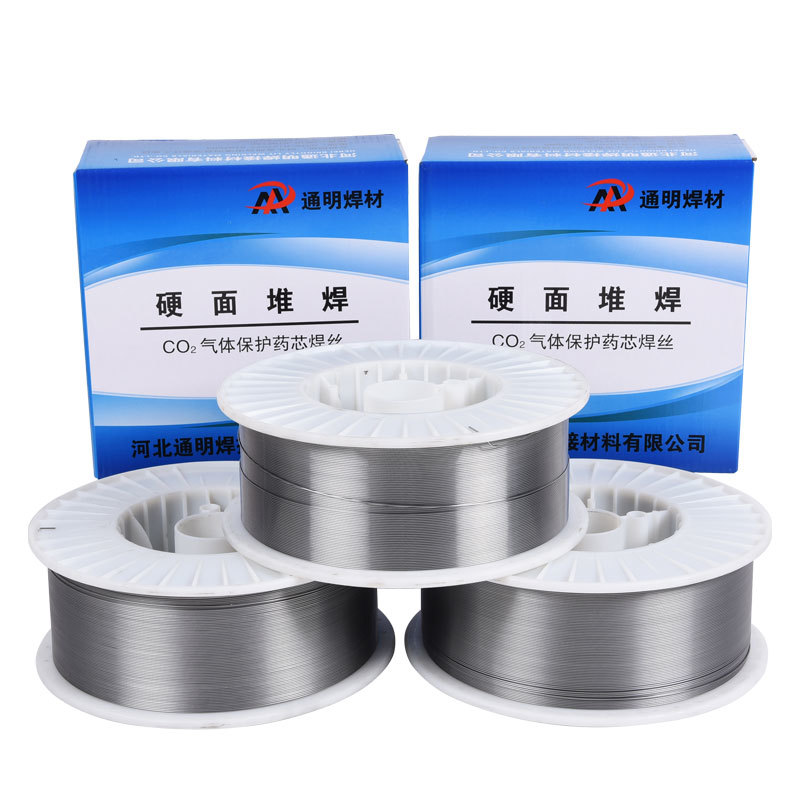

Hard surface wear-resistant surfacing material

Choose Products

Choose Products

Choose Products

Choose Products

Choose Products

TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS

TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS

TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS TONGMING WELDING MATERIALS

ABOUT US

The Leading Welding Materials

Manufacturer in China

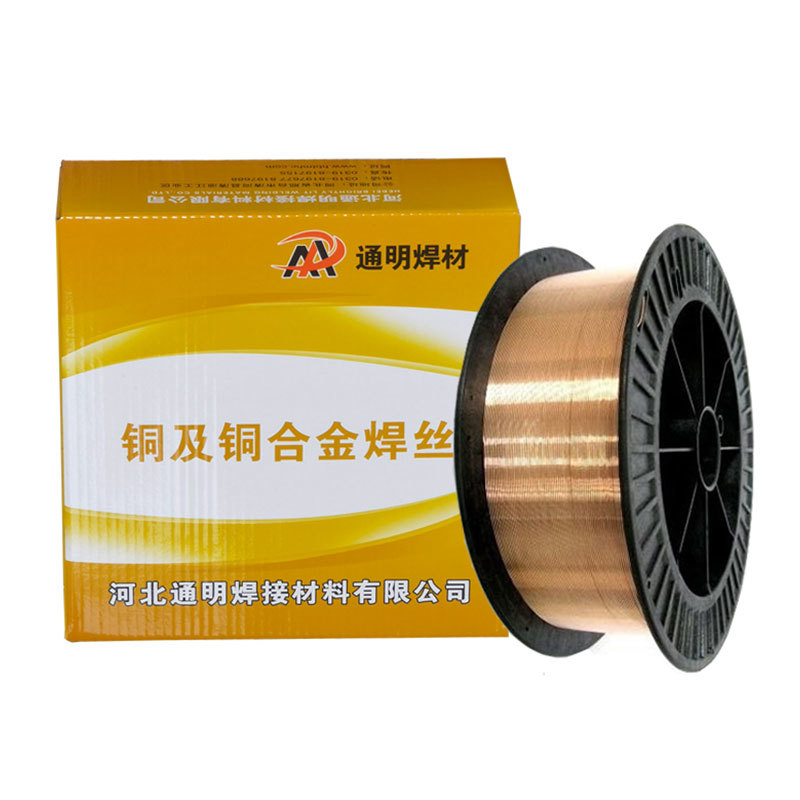

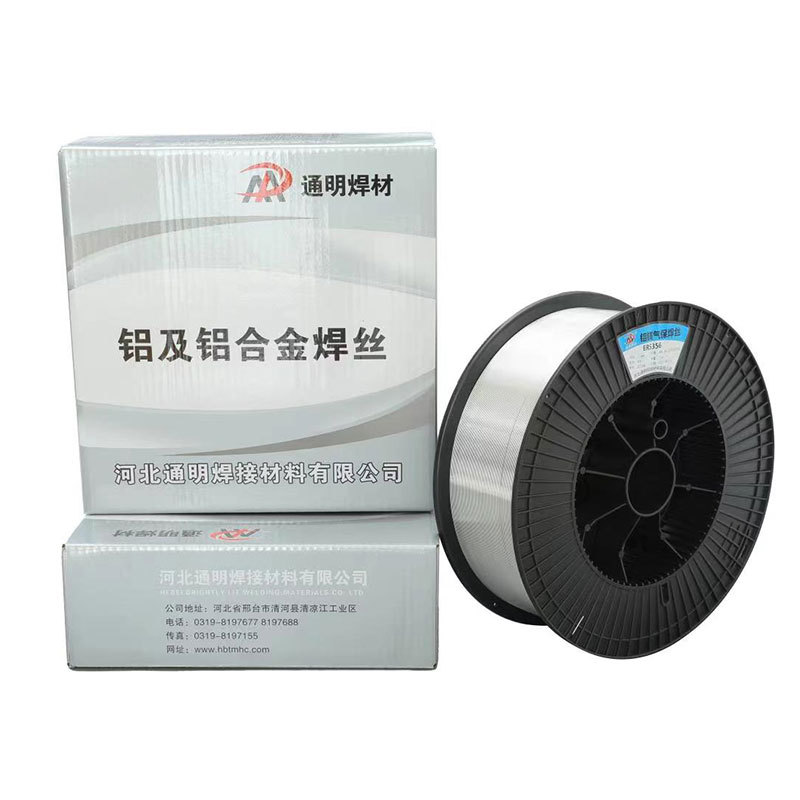

TONGMING is one of the leading welding materials manufacturers in China. Since the inception of our operations in 2002, we have adhered to the highest standards of quality, research and innovation, and customer service. The products mainly include various types of welding materials such as carbon steel, low alloy steel, stainless steel, heat-resistant steel, low-temperature steel, high-strength steel, weather resistant steel, overlay welding, copper, aluminum, titanium, etc.

Total investment of the company

Annual production of welding materials

Exporting countries and regions

Our Capabilities

Our R&D department has been one of the key contributors to the overall sustained growth of the company by developing new welding consumables as well as enhancing the existing ones.

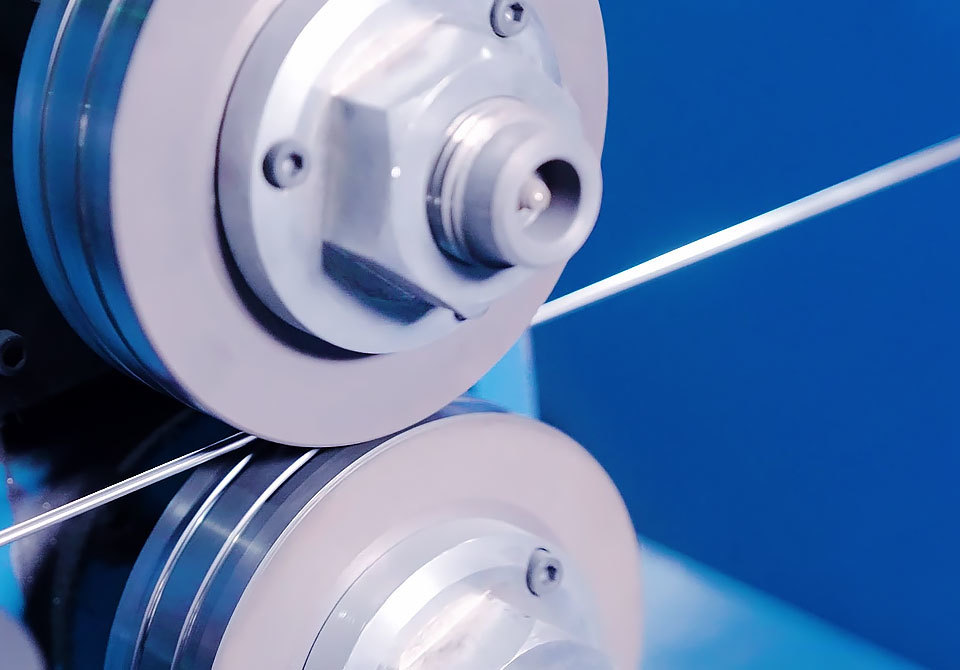

Production Capacity

Introduced world leading production devices which are intelligent efficient environmentally friendly , and energy saving resulting in an annual output of 65000 tons.

Innovation

The company has set up a team of high caliber inter disciplinary talents to research core technologies keep releasing energy in production.

Quality Control

Consistently sets high standards on each target and pay attention to every single detail in order to guarantee the quality of welding materials.

Industries We Serve

The products are widely used in many industries, indluding shipbuilding, offshore engineering, petrochemical engineering, electric power, vehicle industry.

Cement Industry

Shipbuilding

Ocean Engineering

Oil & Gas

Power Genratoin

Manufacturing

Steel Structure

Pipeline

Automotive

TONGMING has been supplying engineered anti-wear hardfacing solutions to Cement Industry and their Original Equipment Manufacturers (OEM’s) for increased efficiency, productivity and lower costs.

Provides welding electrodes and wire with low fume, suitable for zinc primer, anti-cracks, and sound impact toughness at low temperature, and have certified as high quality products by third parties from industries, such as nuclear power boiler and shipbuilding.

Provide the welding consumables with moisture resistance, low hydrogen content, low temperature impact value, high resistance to cracking, strong wind, excellent weldability of marine structures to meet the welding requirement of offshore drilling platform, drilling tower welding.

Our products can be found in service throughout the oil and gas industry - upstream, midstream, and downstream -in some of the harshest applications and environments protecting production equipment and customer profitability against the costly ravages of wear resulting from abrasion, erosion, corrosion, and heat.

In order to meet various power plant demands, TongMing welding materials offer low hydrogen, low impurities, high anti-cracks, high temperature resistance welding electrodes and welding wires.

Provide anti-high temperature oxidation, corrosion resistance, high tensile strength, high impact ductile electrode and wire to meet the welding requirement from food machinery, boilers and pressure vessels, industrial equipment.

Provide welding consumables with high deposition rate, excellent pit resistance, superior crack resistance and good weldability. Products apply to domestic and overseas bridge and building by high tensile steel series.

Provide the welding consumables of low-phosphorus, low hydrogen content, high impact performance, low spatter, deep penetration, strong wind resistance, excellent controlling ability of low-temperature pipe welding with self-shielding wire.

Provide welding consumables of excellent wire feeding ability, low spatter, high welding efficiency of the solid and cored metal wire, to meet the welding needs of automobile structure, exhaust system, car silencer, etc.

BLOG

News & Media

Apr 10,2024

TIG vs MIG – Which Welding Process Is The Best For Your Business?

Apr 10,2024

How To Choose The Right Grade For The Right Applications?

Apr 10,2024

The Basic Guide To The Many Welding Styles And Processes

Apr 10,2024

Everything Every Welder Should Know About Mig Welding

Export Manager: Ms. Wang

Qingliangjiang Industrial Park, Qinghe County, Xingtai City, Hebei Province

Request Quote