-

Products

-

IndustriesThe products are widely used in many industries, indluding shipbuilding, offshore engineering, petrochemical engineering, electric power, vehicle industry.

-

About UsTONGMING is one of the leading welding materials manufacturers in China. Since the inception of our operations in 2002, we have adhered to the highest standards of quality, research and innovation, and customer service.

-

NewsOur products have passed ISO9001 quality system certification, and have certified as high quality products by third parties from industries, such as nuclear power boiler and shipbuilding.

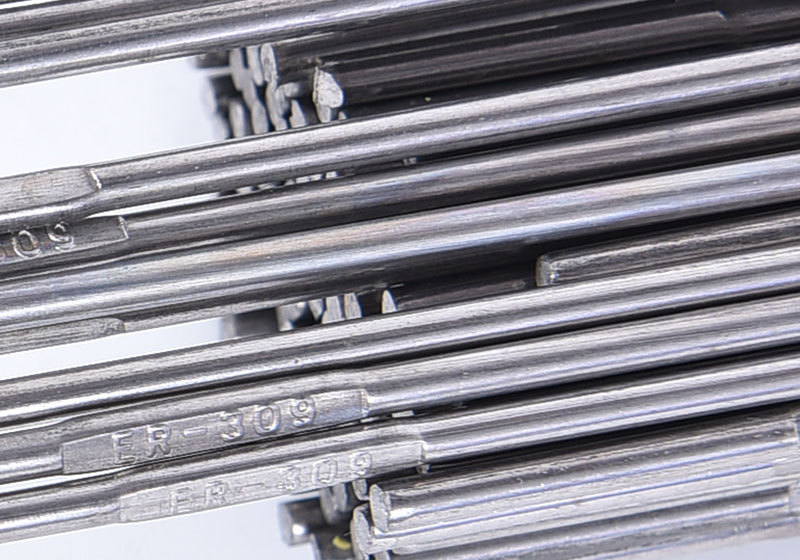

All You Need To Know About Stainless Steel TIG Wire

Apr 10,2024

What is TIG?

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a type of arc welding that uses a non-consumable tungsten electrode to generate a weld.

In the 1940s, tungsten inert gas (TIG) welding became an instant hit for joining magnesium and aluminum. The procedure was a highly appealing option for gas and manual metal arc welding since it used an inert gas shield instead of a slag to protect the weld pool. TIG aided in the acceptance of aluminum as a material for high-quality welding and structural applications.

Practical Applications Of Stainless Steel TIG Wires

Given below are few points that will help you understand applications of Stainless Steel TIG Wire:

★ For welding SS304, use SS 308 since it has a stronger corrosion resistance, which will affect the weld as temperature increases corrosion.

★ Duplex stainless steel – This type of stainless steel has higher strength and is utilized for pitting and crevice corrosion resistance. It can be utilized for a variety of purposes, although their utility is often diminished when employed in normal settings because they are more expensive than other grades.

★ SS TIG Wires can also be used on grades 301 to 304, as well as some types of cast steels – SS 316L for welding SS316L (the marine Grade) and comparable materials since the higher nickel and chromium content gives better corrosion resistance in saltwater and at different temperatures.

★ ER308/308H is used for unstabilized stainless steels such as 301, 302, 304, 304H, 305, 308, and 308H.

★ ER-308L is used to weld base metals with similar chemical compositions, such as AISI 301, 302, 304, 304L, 305, 308, 308L, and 347.

★ ER-309LSi, which has a greater silicon content to improve bead appearance, is primarily used for welding incompatible materials such as mild steel to stainless steel, as a barrier layer in stainless overlays.

Filler Wire

Filler wires are actually used to join materials together. Filler rods are typically not required in TIG welding since tungsten is hard and has the highest melting point of any material. However, filler rods are used in some circumstances where the application may conform to a necessity. Filler rods are frequently dependent on the metals to which they are linked. Although it can range from mild steel to aluminum, Nickel Alloys, Hastelloy Alloys, Monel Alloys and Titanium Alloys.

Contact Us

E-mail :

wsn@hbtmhc.com

Phone/WhatsApp:

+86-13833932888

Address:

Qingliangjiang Industrial Park, Qinghe County, Xingtai City, Hebei Province

Export Manager: Ms. Wang

Qingliangjiang Industrial Park, Qinghe County, Xingtai City, Hebei Province

Request Quote